Before entering the pipeline: Diamond Formation in Earth’s Mantle

A common myth associates diamond formation with coal formation. Many believed that diamonds are simply pieces of coal that have been transformed under a very high pressure and high temperature. This is far from the truth. One reason why is because coal is actually formed from the remains of early vegetation. Diamonds, on the other hand, are much older than the plants which are the main ingredient for the formation of coal.

Most diamonds deposits were formed inside the Earth’s mantle about 90 miles (150 kilometers) below the surface where temperatures are at least 2000 degrees Fahrenheit (1050 degrees Celsius). Diamonds are brought to the surface of the Earth in large chunks of rocks called kimberlite or lamproite, forced upward by violent volcanic eruptions. Not every discovery is economically viable. About 85% of kimberlite discoveries do not contain diamonds.

Diamond Exploration

Diamond exploration is a long, expensive and often unsuccessful process, but when science gets a little help from Lady Luck, big things can happen.

The first stage in diamond exploration is to identify an area with potential diamond deposits. Airborne geophysical surveys are generally used to cover large areas very rapidly. Ground-based geophysical surveys are used to refine any targets identified from airborne surveys and to further investigate potential targets.

Sometimes this process is simplified by a previous diamond discovery. Sometimes soil samples or stream sediments show ‘indicator’ minerals, which are sampled and analyzed. In most cases, the rock that generates an ‘anomaly’ (a strange thing that may point to diamonds below) is buried underneath the surface or is found beneath a lake.

Drilling must then be conducted to investigate the anomaly and recover samples. A drill rig is positioned above the target and a hole is drilled to take a sample of the rock for examination by geologists. Exploration drilling is expensive. If the drill core recovered is not kimberlite, drilling of the anomaly is generally discontinued.

Mining

Diamonds come from two types of deposits; each type requires special mining techniques. Primary deposits, in which diamonds are contained in kimberlite pipes, require open pit or underground mining operations. Secondary deposits are defined as diamonds that have traveled from their original location due to erosion. These require alluvial mining, which uncovers diamonds in riverbed, coastal and marine/undersea locations.

Regardless of the way diamonds are mined, enormous investment and technical skills are necessary to construct, maintain and operate a mine. In open pit and underground mines, the ore is crushed to uncover the diamonds. Coastal mining involves the excavation of sand to find diamonds. Undersea mining entails drilling into the seabed to recover diamond-bearing gravels. Riverbed mining is often on an informal, smaller scale — also known as artisanal digging — and involves the most basic of equipment, such as sieves and pans, to find diamonds.

Rough Sorting & Valuing

Once mined, rough diamonds are delivered to sorting experts who categorize and assign a value to them. It is here that industrial quality diamonds – which are small, lower quality stones – are identified and separated from gem-quality diamonds. These industrial diamonds are then used in equipment such as drill bits and lathes.

Diamonds of gem quality are classified into thousands of categories based on size, shape, quality and color. The majority of diamonds fall within a range of standard colors. Almost all rough diamonds have some distinguishing marks, known as inclusions, which make each one unique. Sorting diamonds is a crucial step in the valuation process. Dividing gem-quality diamonds into commercial ‘parcels’ requires extensive knowledge of the cutting and polishing procedures that follow, as well as keen awareness of market demand.

Rough Trading

Rough diamond trading occurs through several channels, but always under Kimberley Process regulations (rough diamonds may only be traded in and with countries that participate in the KP). The two largest diamond producers, Russia's ALROSA and the famous diamond miner De Beers, trade the majority of their stones to companies under long-term contracts. Each of these companies has about 80 contracted customers which are obliged to purchase a 'parcel' of diamonds at approximately ten sales per year. In turn, the contracted companies are assured of a consistent supply of rough diamonds.

The other diamond producing companies trade their diamonds at auctions and 'tenders' in the major diamond trade centres, such as Antwerp, Tel Aviv or Dubai. Antwerp is by far the largest trading centre due the very large number of diamond companies and services located in a small area. A tender is a type of 'blind' auction common to the diamond trade due to its fairness, and because it is the best way to set a correct market price. The larger mining companies are also usually obliged to make a certain percentage of their diamonds available to the local market for manufacturing.

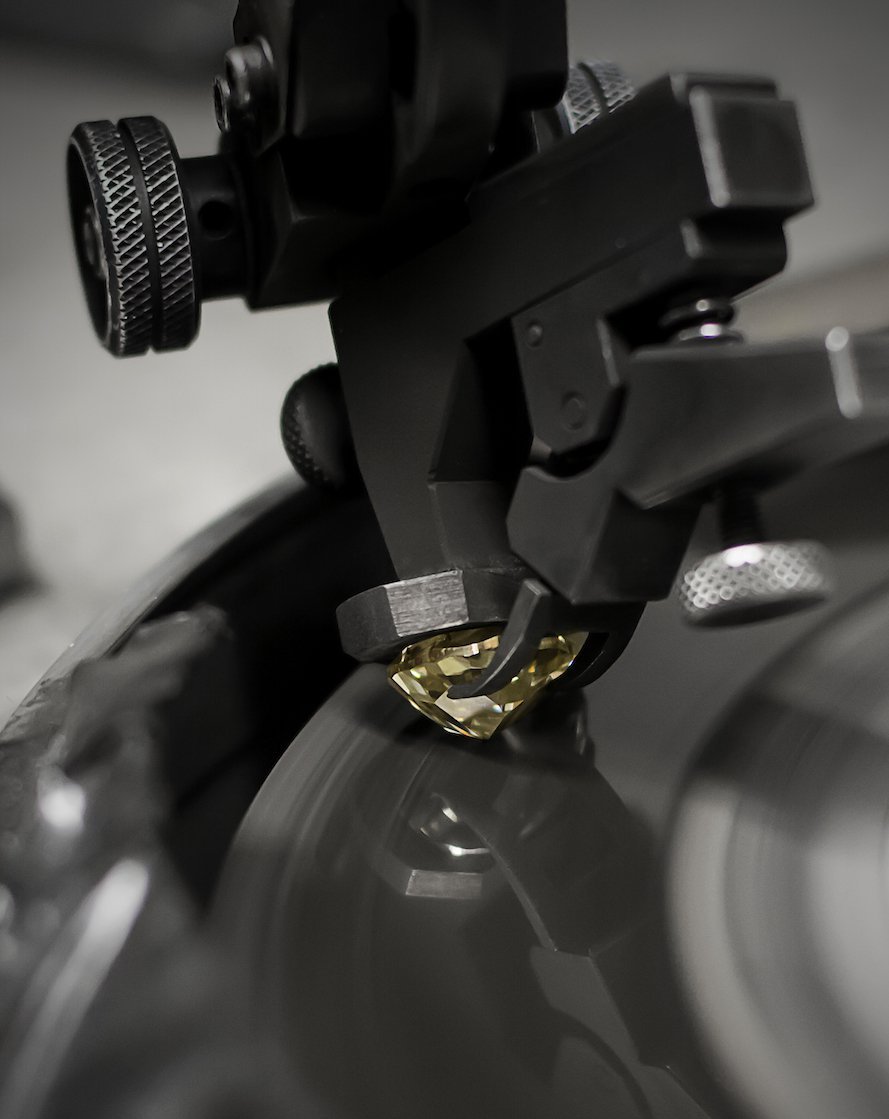

Cutting and Polishing

After sorting, the diamonds are cut and polished. Cutting a rough diamond takes great skill, and increasingly technical sophistication. In recent years, technological tools and software have advanced to the stage that automated analysis, or ‘mapping’ of rough diamonds show the most efficient way to get the best polished yield from a rough stone. The first stages of diamond polishing can now be accomplished by automated machines, but the precision work is still done by hand. The largest polishing center is India, but is still done all around the world, in New York, Antwerp, Israel, China and Russia, among other countries.

A well-cut diamond reflects light within itself, from one facet to another, as well as through the top of the diamond, bringing out its spectral brilliance. The most popular cut is the 57-facet round brilliant. After a stone has been cut, it is then polished and classified again, this time by its cut, color, clarity and carat weight, also known as the “Four Cs.”

Polished Diamond Trading

Once stones are cut and polished, it's time to get them into the hands of jewelry manufacturers. Diamonds polished in India (the largest centre), if not manufactured on the spot, are typically traded by Indian companies on the markets in Antwerp, New York, Tel Aviv, Hong Kong, and wherever one of the thirty-one diamond bourses are found. These sales typically take place in the central and regional offices of the diamond cutters, and sometimes at exhibitions that are held in different cities around the world. The two biggest are held each year in Hong Kong and Las Vegas.

Once polished diamonds enter the market, they will often change hands many times among traders and wholesalers. A typical route might be this: a large Antwerp company that is a contracted De Beers buyer sends its diamonds to be manufactured in India; after they are polished, they ship them back to their offices in Antwerp, New York, Tel Aviv and Dubai where they will sell them to wholesalers and traders, who in turn may sell them to other traders or jewelers for manufacturing.

Jewelry Manufacturing

After being cut, polished and categorized, diamonds are then sold by traders registered with one of the 31 diamond ‘bourses’ (exchanges) located around the world, or directly to wholesalers or diamond jewelry manufacturers. Manufacturers craft diamond jewelry commissioned by a retailer or other jewelry designers. India is considered the hub of the global jewelry market because of its low costs and availability of high-skilled labor. It is the world’s largest cutting and polishing centre for diamonds, and the polishing industry is well supported by government policies. The gem and jewelry sector plays a significant role in the Indian economy, and also employs over 4.5 million workers.

In the US, the profitability of individual companies depends on efficient operations and cost controls. Large companies have advantages in offering a broader product line to meet consumers' changing desires, and in efficient production and distribution operations. Small companies can compete effectively by offering individualized and unique product lines. The US industry is concentrated: the 50 largest companies account for about 70% of industry revenue. About 90% of US jewelry manufacturers have fewer than 20 employees.

Retail

This is generally all that most people see of the diamond industry: diamond jewelry in the shops and online. Bridal diamond jewelry is still the foundation of the market, but products popular with Millennials and increasing levels of female self-purchase are helping to spur growth. Global consumer demand for diamond jewelry increased marginally to $80 billion in 2016.

Consumer demand in the US, which remained the world's largest market (47%), climbed more than 4% to exceed $40 billion for the first time, supported by job creation, wage growth and a strong stock market. Retailers in China, the second largest (16%) and fastest growing market for diamond jewelry, expect demand to continue to grow. The country has seen diamond jewelry consumption more than triple in the last decade. Demand from Chinese consumers grew slightly in 2016, at least in local currency, but saw a decline in US dollar terms to around $10 billion. The Gulf region (7%), India (6%) and Japan (5%) are the other largest consumers of diamond jewelry.